SS 304 Kunci Stainless Steel Stainless Steel kanggo tali banding

| Jeneng | SS 304 Kunci Stainless Steel Stainless Steel kanggo tali banding |

| Werna | wuda |

| Ketebalan | 0.4mm 0mm 1mm 1mm 2mm |

| Jembaré | 8mm 12mm 16mm 19mm 19mm 19mm |

| Paket | 100pcs / Paket Kanthi Label |

| Fitur | Asam lan Korosi tahan |

| OEM | ditampa |

| Dianggo | Aplikasi banding |

| Wektu Pangiriman | 1 ~ 3 dina miturut jumlah sampeyan |

| Suhu | -60 ~ + 150 |

| Ngatur | ditampa |

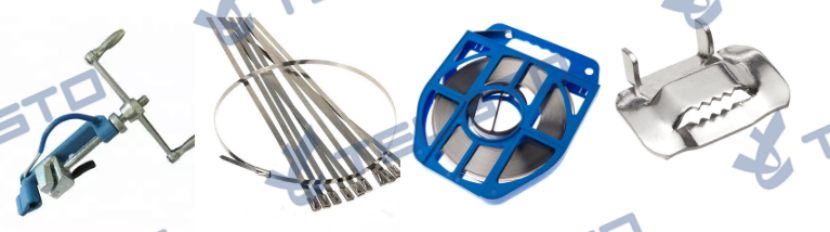

Fitur Produk:

1 .. Buckles kunci kuping bisa digunakake kanthi pirang-pirang jinis band baja tahan karat sing nyedhiyakake kekuatan sing diikat.

2 .. Gaun gaya kuping kanggo aplikasi tugas standar kalebu Sidang Hos, Banding kabel lan fastening umum.

3. 201/304/316 stainless steel nawakake resistensi kanggo oksidasi lan agen korotif sing moderat.

4. Sampeyan bisa nahan konfigurasi band band siji utawa dobel.

5. Clamp band bisa dibentuk liwat bentuk kontur.

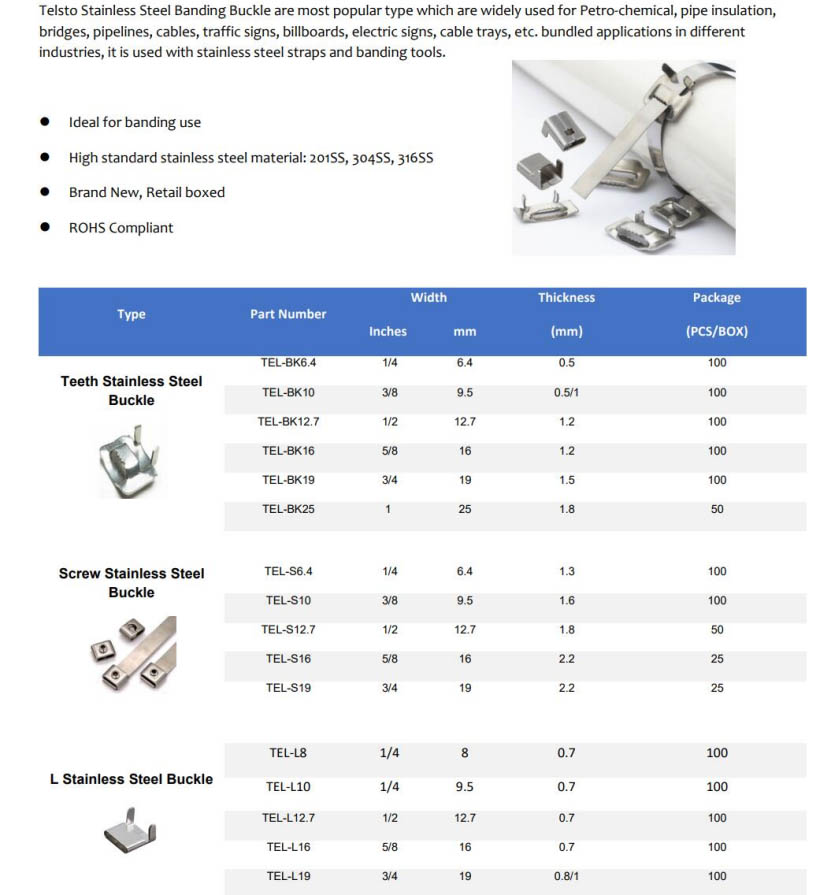

| Ketik | Nomer bagean | Jembaré | Ketebalan | Bahan steel stainless steel | Paket |

| mm | (mm) | (PC / PACK) | |||

| Buckle Stainless Steel Buckle | Tel-BK-32X2.4 | 32 | 2.4 | 201/304 | 100 |

| Tel-bk-25x2.4 | 25 | 2.4 | 201/304 | 100 | |

| Tel-bk-19x2.4 | 19 | 2.4 | 201/304 | 100 | |

| Tel-bk-19x1.5 | 19 | 1.5 | 201/304 | 100 | |

| Tel-BK-19X1 | 19 | 1 | 201/304 | 100 | |

| Tel-BK-16X1.5 | 16 | 1.5 | 201/304 | 100 | |

| Tel-BK-16X1 | 16 | 1 | 201/304 | 100 | |

| Tel-BK-12.7X1 | 12,7 | 1 | 201/304 | 100 | |

| Tel-bk-12.7x1.5 | 12,7 | 1.5 | 201/304 | 100 | |

| Tel-bk-10x1.2 | 10 | 1.2 | 201/304 | 100 | |

| Tel-bk-10x1 | 10 | 1 | 201/304 | 100 | |

| L stainless steel baja | Tel-lbk-10x0.7 | 10 | 0,7 | 201/304 | 100 |

| Tel-lbk-20X1 | 20 | 1 | 201/304 | 100 | |

| Tel-lbk-6.4x0.7 | 6.4 | 0,7 | 201/304 | 100 | |

| Tel-lbk-20X1 | 20 | 1 | 201/304 | 100 | |

| Tel-lbk-19x1 | 19 | 1 | 201/304 | 100 | |

| Tel-lbk-16X1 | 16 | 1 | 201/304 | 100 | |

| Tel-lbk-12.7x0.8 | 12,7 | 0,8 | 201/304 | 100 |

Pandhuan instalasi n utawa 7/16 utawa 4310 1/9 "kabel fleksibel super

Struktur Konektor: (Fig1)

A. nut ngarep

B. BACK BACK

C. Gasket

Ukuran stripping minangka ditampilake diagram (Fig2), perhatian kudu dibayar nalika stripping:

1. Lumahing mburi konduktor ing mburi kudu disuda.

2. Copot impurities kayata skala tembaga lan burr ing mburi kabel.

Mumpuni bagean panyeget: ngawut-awut bagean panyesuaian ing sadawane konduktor njaba kabel kaya sing dituduhake diagram (Fig3).

Mumpuni nut mburi (Fig3).

Gabungan nut ngarep lan mburi kanthi strewing kaya sing dituduhake dening diagram (Figs (5)

1. Sadurunge ngaco, smear lapisan pelumas pelumas ing o-ring.

2 .. Terus nut mburi lan ora obah kabel, ngawut-awut awak cangkang utama ing awak cangkang mburi. Nyawut awak cangkang utama awak mburi nggunakake wrench monkey. Ngrakit rampung.